Conversions get very confusing easily, especially when the standards are defined differently for different items and are also different across countries. It is important to understand what do the terms mean for a medical device manufacturer.

Here are the basics:

The standard Standards are below and they are all linear simple formulas to correlate with each other:

1 micron: 1 micrometer = 0.001 mm =0.0001 cm = 0.000001 meters.

1 inch = 25.4 mm.

Now comes the fun part:

1Mil is defined as a thousandth of an inch = 0.001 inch = 0.00254 mm =25.4 microns

A gauge is loosely defined as 100th of a Mil. Thus, 100 gauge is 1 mil thick but each industry has created their own definitions.

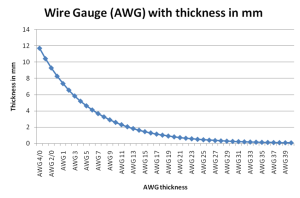

WIRES: For wires if “gauge” is a definition of a pipe (say a needle or wire) then there is an inverse relationship between the gauge and the thickness. And it is NOT linear. Thus, the higher the guage, the thinner the wire or needle. This was derived from the three directional cross sectional area of a solid round cylinder and for American Wire Gauge (AWG) that is used for electrical wires it is loosely based on electrical resistance or the electricity carrying capacity. However, this can really mess up medical device designs since they are not linear as the graph shows.

So look at the chart below. Not only is the chart inverse but it follows a loose log curve. Therefore, deciding on the thickness of the wire or needle or tubing while reading its AWG can get confusing. Watch out!

SHEETS – PLASTIC: The relationship is generally linear and correlative. Therefore, an increase in gauge/mil means an increase in thickness, but every vendor seems to do their own convenient conversions. The plastic vendors selling sheets of plastic are the best and, they generally express thickness of their sheets as Mil and equate 1 Mil to 25.4 micrometer, which incidentally is the average diameter of human hair. They also recognize a Gauge as 0.254 micrometer. In pool liner business, all bets are off. Some do their own conversion: they equate mil with gauge and use mil and gauge interchangeably!

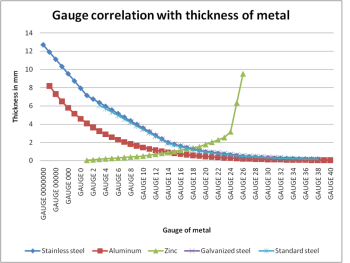

SHEETS – METAL: In this case the Gauge is measured by the weight rather than the thickness. Since the density of different metals varies, so does the gauge. In the devices, therefore be careful of the metal that is used to create the device. The gauge may be very different for each metal and totally illogical with Zinc as the chart below shows.

In short watch out for “Gauge” as a unit of measurement.